Providing the best route

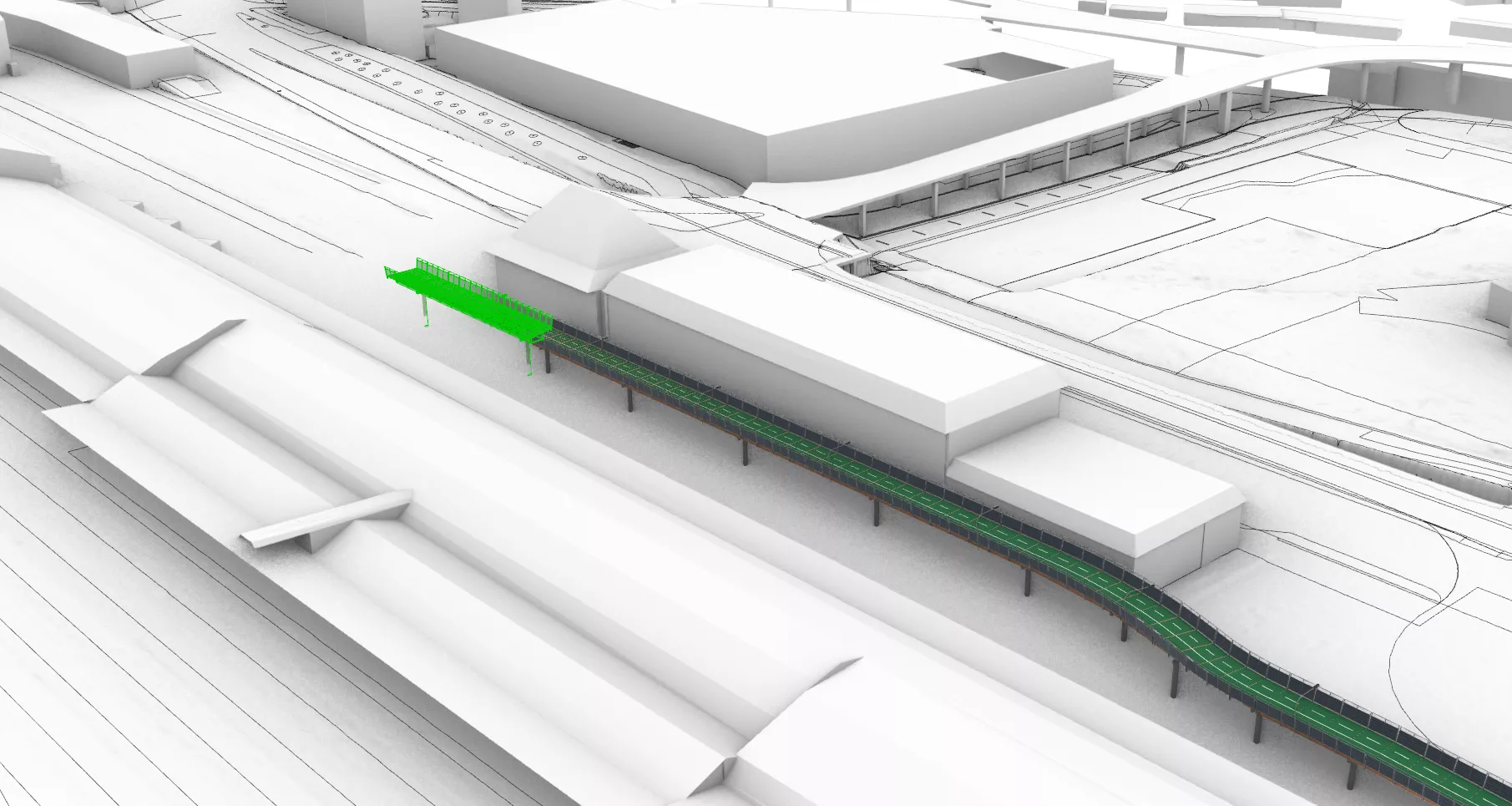

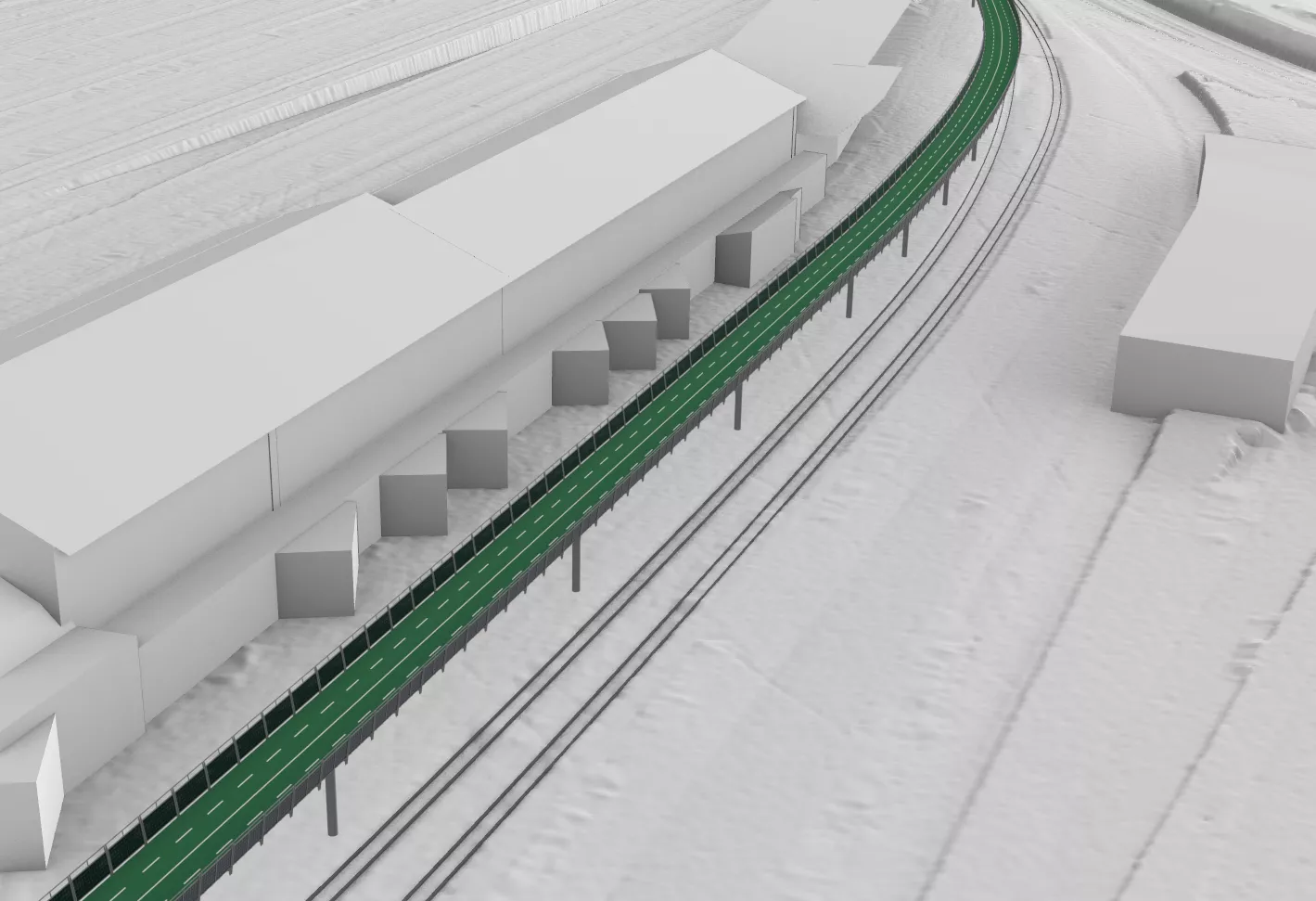

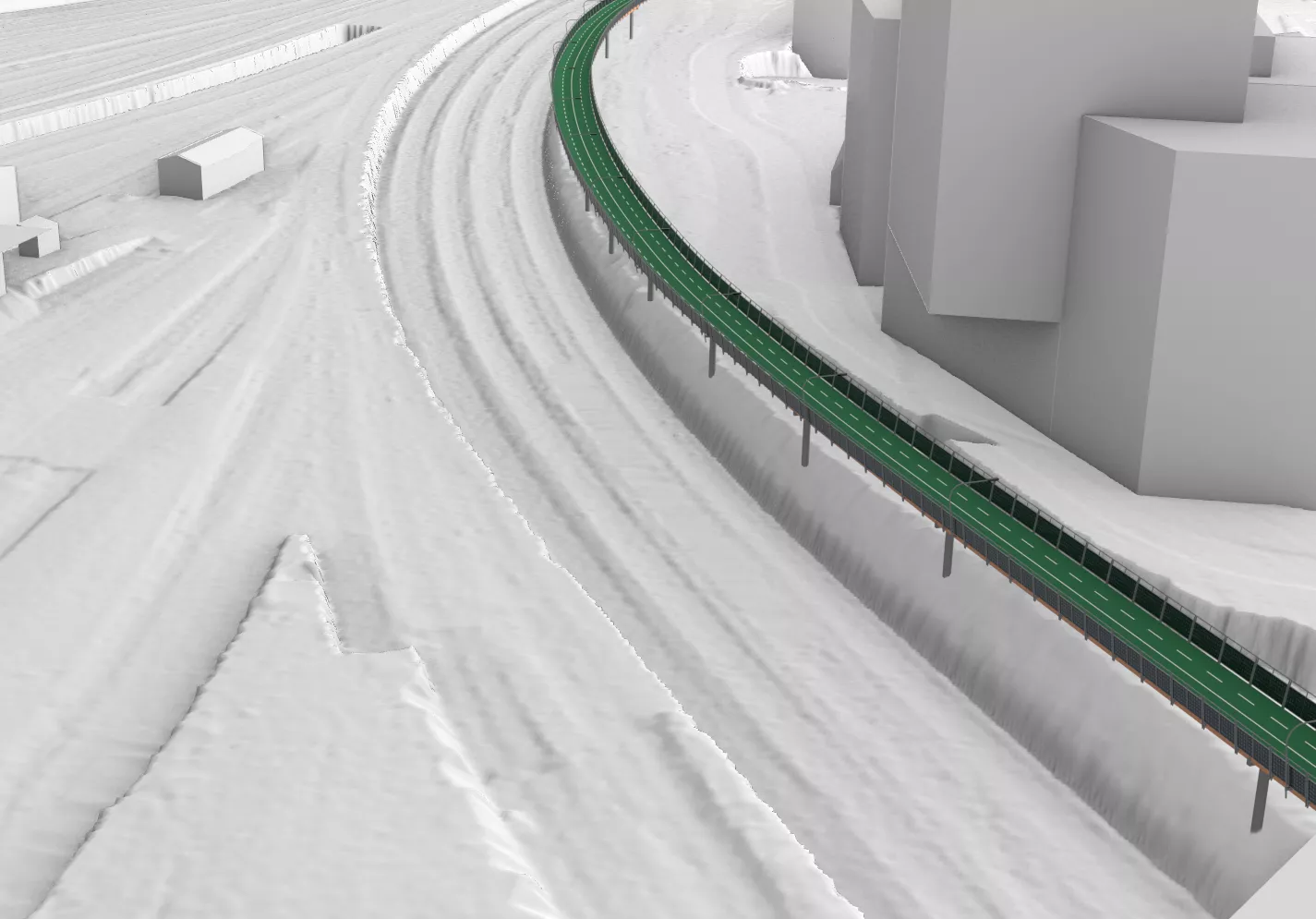

Cycle paths are usually built at ground level and directly next to busy roads. Consequently, cyclists often have to overcome differences in elevation on their journey, following the course of the road, rendering cycling less attractive.

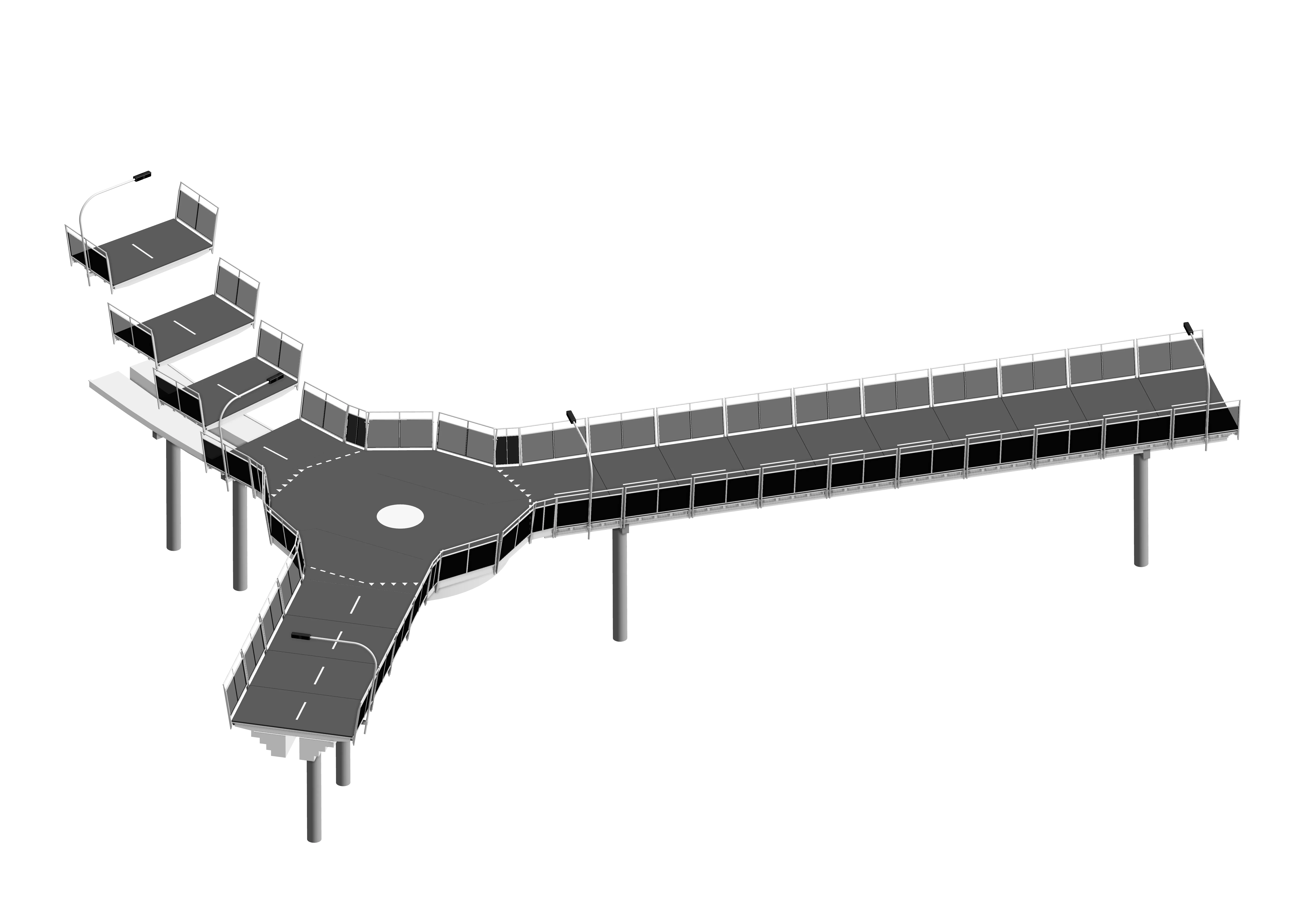

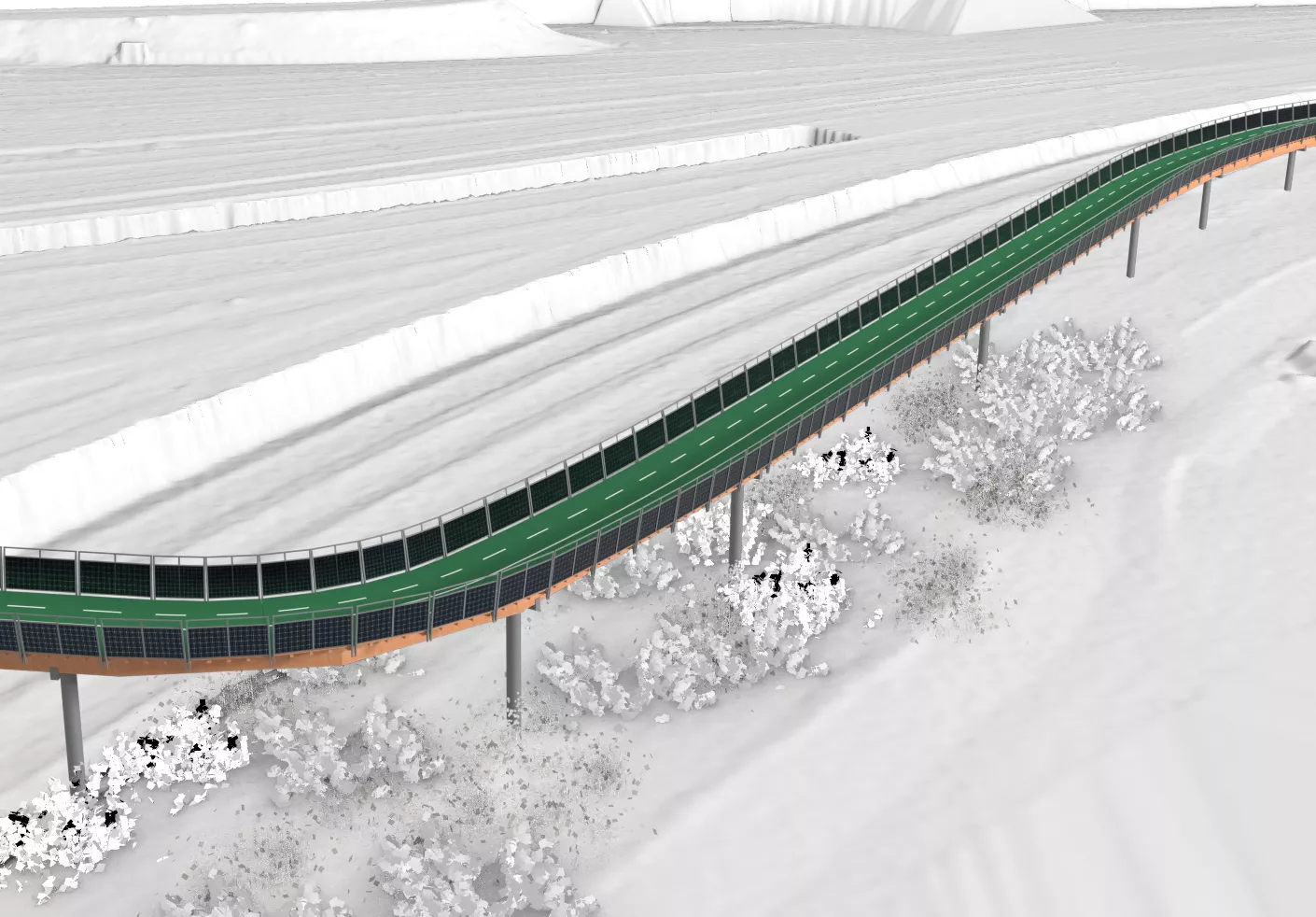

Apart from offering an unprecedented experience and safety, elevated cycle paths enable direct cycling on an even level. As a complementary option to the ground-level cycling infrastructure, we provide owners and planners with a further instrument to increase the attractiveness of cycling.

How to get the urb-x products

Are you interested ?

Do you have a question ?

Do you want to become our partner ?